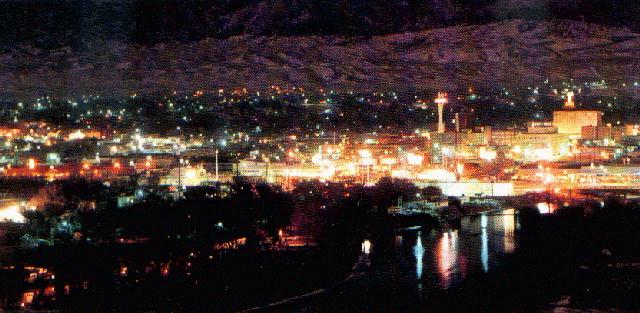

Company Location

Wickman Spacecraft & Propulsion Company is located in Casper, Wyoming at the Casper/Natrona County International Airport. CP Technologies, our sister division, operates out of the same location. Casper is a great place to live and work with no state income tax. It has a population of about 50,000.

Company Address: 3745 Studer, Casper, Wyoming, 82604

Company Employment

Wickman Spacecraft & Propulsion Company (WSPC) specializes in high risk, high payoff research and development projects for the Department of Defense, NASA and commercial contractors. WSPC’s track record has been highly successful in over 25 years of business.

Currently, we have no intern, temporary or permanent employment positions open.

Note: US citizenship is required of all WSPC employees due to Department of Defense and NASA requirements. WSPC is an equal opportunity employer. Qualified applicants will receive consideration for employment without regard to race, color, religion, sex, or national origin.

Company History

Wickman Spacecraft & Propulsion Company was incorporated in 1981. It was located at that time in Sacramento, California. Initially, the company was only doing small consulting contracts until the Space Shuttle Challenger accident in 1986.One of Mr. Wickman’s areas of expertise was solid rocket motor failure analysis. This enabled WSPC to obtain consulting contracts for the Shuttle SRB field and nozzle joint redesign and the Titan SRB recovery program. About this time, Mr. Wickman and Dr. Adolf Oberth teamed up to take the company in the direction of research and development. Dr. Oberth is a world renown propellant chemist with a list of patents that goes on for pages. As a historical footnote, Adolf is the son of German rocket pioneer, Hermann Oberth.

As a partner in the company, Dr. Oberth wanted to pursue some new ideas he had for phase stabilizing ammonium nitrate for use in solid rocket propellants. In 1987, he submitted a Phase I SBIR proposal to the Air Force and won. At the time, WSPC facilities consisted of Wickman’s and Oberth’s garages. John Wickman was able to procure additional contracts. WSPC had definitely outgrown Wickman’s and Oberth’s garages, so they leased their first facility (right). It was a tough proposition as most places did not want to rent to companies with hazardous materials who were doing rocket propellant testing. After a long search, WSPC located in a small facility in North Highlands, California in the suburbs of Sacramento.

One of the great things that enabled WSPC to grow was Government surplus sales. Dr. Oberth and Mr. Wickman would go to the auctions and buy all kinds of rocket materials, equipment, tables, chairs, instrumentation and anything else that might be useful for pennies on the dollar. Often the purchase of several auction lots would fill an entire Ryder truck. The unloading was often a struggle as Oberth and Wickman would have to unload heavy equipment by hand. In the case of an Instron Tensile tester, they were able to borrow a forklift to get it off the truck after struggling for over an hour to move it by hand. Oberth and Wickman took a well earned break after getting into their first laboratory (Right).

With their new facility, Wickman started work on developing a lunar soil propellant composed of a metal powder suspended in gelled liquid oxygen. He looked at a variety of metal powders that could be obtained from processed lunar soil. The project was successful with aluminum powder suspended in gelled liquid oxygen, which was the best performing propellant combination. Just as the program was to go into follow-on phases, the funding from NASA was pulled and given to the International Space Station. The ISS was overrunning its budget and was sucking up money from many projects even in the early 1990’s. While President Bush and Vice President Dan Qualye were promoting a return to the moon with a lunar base, the first signs were being noted that NASA’s goals were way too big for it budget. Still, things were upbeat at WSPC and they put up their biggest AIAA exhibit ever which drew a good size crowd.

In 1988, Eric James joined WSPC bringing his architectural and engineering background to the company. One of Mr. James’s early projects was the design of a lunar base. Mr. Wickman decided if WSPC was working on lunar soil propellants, it was only logical to start looking at the base where they would be used by lunar settlers. For the lunar base, it was decided to make use of the lunar soil to form lunar concrete. Mr. James designed a base making use of this new material.

The facility in North Highlands had also grown too small for WSPC. So, Wickman and Oberth started looking for a larger place. It was hard finding a facility that had the proper zoning where the landlord would permit them to test rocket engines. They did find a place just outside of Roseville, California on the outskirts of Sacramento. In the new location, the field was several acres which allowed the company to test much larger rocket engines than the facility in North Highlands.

While working on the Lunar Soil Propellant contract, the idea came to Mr. Wickman that perhaps this same approach could be used with earth propellants. Mix the fuel and oxidizer together to form a monopropellant. This would eliminate half of the plumbing and hardware associated with conventional liquid rocket systems. One set of expensive tanks, lines, valves and pump would be gone. It also seemed to Wickman that the injector of the engine could be greatly simplified with this approach. The idea was proposed to NASA and WSPC won a contract to explore a variety of fuels suspended in liquid oxygen.

This was one of the more interesting projects for WSPC as a wide variety of fuels were tried with the liquid oxygen. They ranged from ground up tires to coal. Just about anything that could potentially work was tried first for shock sensitivity and then tried in a simple combustion test. The best fuel candidates were K1 kerosene and regular motor oil. Since kerosene had the best performance, WSPC selected that one to pursue in Phase II of the project.

During 1992, the city of Roseville purchased the land next to WSPC’s facility and began construction of a large office complex. It was clear that when their facility was finished, WSPC’s activities in the adjoining field would be finished, too. By this time, it was clear to Wickman that economics, not technology was going to be the driving force behind Space exploration. If it could not be done at an affordable price, then it was not going to be done by the United States or any government. The company begin to reorient itself towards the goal of low cost access to Space. Plans were started on a launch vehicle using WSPC’s liquid oxygen/kerosene monopropellants as well as their PSAN solid rocket propellant. This work could not continue in California, so it was time to look at relocating to a new state.

After a long search that included just about every state in the US, Wickman narrowed the choice down to three states; Wyoming, Nevada and Colorado. After a through investigation of all three states, including on-site visits, Wyoming was selected as the best choice for WSPC. Once Wyoming was selected, Casper was chosen as the best city to relocated to within the state. In 1992, WSPC purchased a 60 acre facility in Casper on the north side of town and began getting ready for its move. In February 1993, WSPC moved from California to Casper, Wyoming.

As WSPC set up its equipment in its new facility in Casper, the entire aerospace industry started to downsize. This was the era of major aerospace companies going into bankruptcy or being purchased by other companies. Wickman knew tough times were laying ahead when large companies like Hercules were calling WSPC looking for contract work. A major NASA contract that had been expected to continue work on the LOX/kerosene monopropellant rocket engine did not materialize. It was time for WSPC to downsize along with the rest of the aerospace industry. They gave up their 60 acre facility and Dr. Oberth retired.

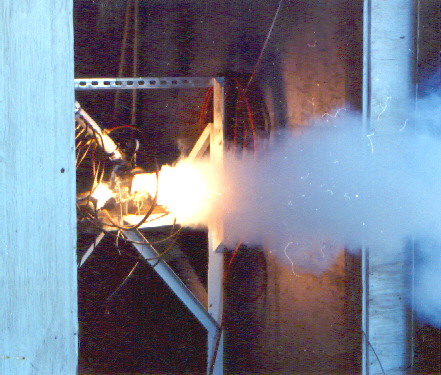

In 1995, WSPC started work on new contract for JPL to develop a rocket engine and jet engine that could directly burn the Martian atmosphere of carbon dioxide. This was not going to be an easy task as the Martian atmosphere is essentially carbon dioxide, a common gas used in fire extinguishers. WSPC was going to take up the challenge of developing a rocket and jet engine that would burn what was commonly used to put out fires. The key was to use magnesium powder, which would readily burn with carbon dioxide. WSPC leased a new facility to conduct rocket engine tests on this revolutionary new propulsion system. The new facility was in Mills, Wyoming located next to Casper, Wyoming.

The work on the Mars rocket engine was successful as was the Martian jet engine. The jet engine proved to be a particular challenge for WSPC engineers as the magnesium powder had to be introduced into the combustion chamber at a very controlled rate when the engine was started. While it was difficult, WSPC was able to repeatedly start the jet engine and operate it. W SPC also tested a burner operating under the low pressure conditions that would exist on Mars. These tests were successful showing that a Mars jet engine for powering a flying rover or Mars airplane was feasible.

During this time, WSPC started work on a series of low cost sounding rockets and launch vehicles using the PSAN propellant the company had invented during the 1980’s. Mr. Wickman began reformulating the propellant for easier and cheaper processing. He also lead a in-house R&D program to develop low cost solid rocket motor designs. The company also began conducting a series of subscale flight tests on the high plains of Wyoming.  The primary focus of the flight tests were to study shifts of the center of pressure during flight up to sonic speeds and evaluating various multiple deploy schemes for rocket recovery. WSPC engineers also started evaluating various methods for guidance and control, which included the use of commercial inertial measurement units (IMUs) and industrial PC boards. A series of sounding rocket designs were developed along with a low cost small launch vehicle design.

The primary focus of the flight tests were to study shifts of the center of pressure during flight up to sonic speeds and evaluating various multiple deploy schemes for rocket recovery. WSPC engineers also started evaluating various methods for guidance and control, which included the use of commercial inertial measurement units (IMUs) and industrial PC boards. A series of sounding rocket designs were developed along with a low cost small launch vehicle design.

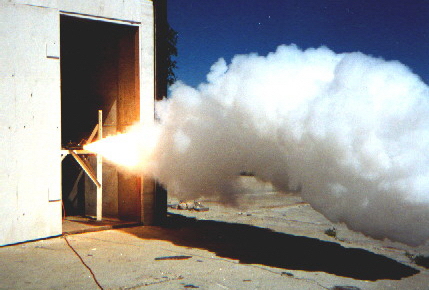

In 2000, WSPC moved to its current facility at the Natrona County International Airport just outside of Casper, Wyoming. During this time, NASA Ames was looking for ride to test a subscale version of their SHARP vehicle. WSPC proposed a modified version of one of their sounding rockets and won a contract to conduct a launch of the SHARP vehicle. A launch facility was constructed north of Casper and the solid rocket motor for the sounding rocket was built and tested. The motor incorporated all of the low cost design features WSPC engineers had been working on for five years. The motor contained approximately 1,100 lbs of propellant with a burn time of 30 seconds. It was 18 inches in diameter with a length of 10 feet.

The initial part of the test was successful until a suspect seam weld on the motor case failed at maximum operating pressure. A new seamless motor was built and ready for static testing when the SHARP flight program was cancelled along with other NASA flight programs in 2001. WSPC is working on a SHARP launch vehicle concept with subscale testing scheduled for 2020.

Under Air Force contract in 2006, WSPC designed a low cost small launch vehicle using innovative, low cost guidance and control schemes. The vehicle uses a phase stabilized ammonium nitrate solid propellant with a unique expansion-deflection exit cone. This new vehicle can put 2,000 lbs into LEO with a launch cost of $4.6 million. WSPC is currently looking at scaling down this technology for the smaller satellite market.

WSPC has developed a whole new class of solid propellants that can be ignited in a hard vacuum. This new class of propellants can be tailored to burn slow or faster than any existing solid propellants or faster than pressed black powder. These new propellants lead themselves for long term use in space or on deep space missions.

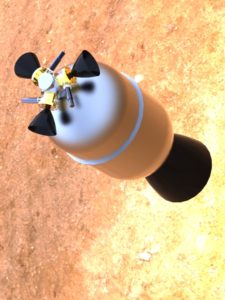

A Mars sample return solid fueled rocket motor was designed for NASA in 2012 with hot gas thrusters for steering. This work is continuing in 2020 with WSPC spinning off this technology for the developing a new solid fueled transfer vehicle that can take small satellites from LEO to the moon or Mars.