Lunar Concrete for Building

With the development of Lunar Soil Propellants, our company became interested in the development of lunar bases. When a base is finally established on the moon, it will need to be as self sufficient as it can with respect to a variety of needs such as food, water, oxygen, energy, propellant and building materials. One area of research our company has been pursuing is the use of lunar materials to make buildings on the moon and in space. Dr. Lin of Construction Technology Laboratories first explored the concept of using lunar concrete as a building material. The use of lunar concrete to build a lunar base and other support structures would eliminate much of the need to bring materials from earth. Research has indicated that lunar soils can be used to make Portland cement, but this approach has one major drawback. It requires water. If water is on the moon, using it for lunar concrete may not be one of its best uses as the water would be lost forever in the formation of the concrete. Our company has chosen to pursue the development of cement based on a polymer, which does not require the use of water. Unfortunately, typical polymers that can be used as a binder or cement require hydrogen and carbon atoms to form the required binder molecule. Neither of these atoms is available in significant quantities on the moon. However, lunar cement might be made with silicates. Our current research is focusing on the use of a sodium silicate type adhesive mixed with fibers to serve as a concrete binder or cement. The lunar concrete properties can be tailored with the amount of fibers in the cement. The fibers can be silica, aluminum, iron or magnesium. This type of cement can be made with materials found on the moon.

The use of concrete requires building forms. WSPC is looking at the possibility of using the concrete to form structural members such as tees, channels, beams, rails, flat sheets and columns through an extrusion process. While the extrusion of concrete shapes is not uncommon on earth, the shapes are somewhat limited. With the lower lunar gravity and a thicker concrete due to the addition of fibers, the extrusion of these more complicated shapes should be possible.

The use of lunar concrete flat panels and beams can be used to make hexagonal rooms, which can be stacked on top of each other to form a large habitat. The building is sealed to eliminate air leakage by spraying the inside walls with a polymer material. The air pressure inside the building trying to blow the walls out can be counter balanced by piling lunar soil on top of the building. This also provides radiation protection to the inhabitants.

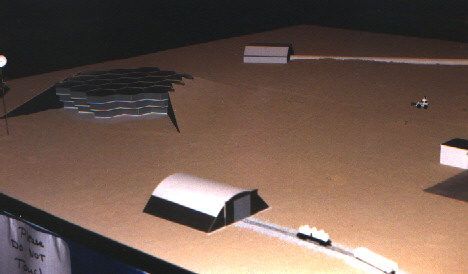

Using demonstrated technology of making concrete from lunar soil, Eric James designed a lunar base made from lunar concrete. His designs were shown at a major lunar base conference at our company’s exhibit room. Shown right is a rail gun to shoot materials/propellant into lunar orbit for use by a lunar space station, left is the main building made of lunar concrete, far right is part of a lunar concrete landing pad and at the bottom left is a terminal building for a lunar railroad.

While lunar concrete is commonly mentioned for use in buildings, our company is looking at its use to make rails for a lunar railroad. The top and inside portion of the rail would be sheathed with iron from the moon. The railroad ties would also be made out of concrete. While many envision flying transportation systems on the moon, the use of a railroad would require the least amount of fuel to move passengers and cargo from one lunar base to another or some other site on the moon. The energy for the locomotives engines could come from the burning of LOX and one of the fuel candidates mentioned for lunar rocket engines.

Lunar Concrete For Orbiting Structures

Another application for lunar concrete may be to build orbiting structures in space. These could be in lunar or earth orbit. This approach could be particularly attractive for building a GEO space station around earth. The building materials from the moon could be shot into space through a rail gun located at the lunar base. They would not have to be taken from earth up to orbit where the propulsion requirements are enormous climbing out of earth’s gravity well. Our company has been investigating the use of an inflatable concrete form to make these orbiting structures. The inflatable form consists of an inner and outer membrane with netting just under the outer membrane. The netting provides tensile reinforcement as well as gives it shape. It also gives a structural redundancy so that catastrophic failure is less likely. The inner membrane of the form is the inner surface holding the concrete as it cures. It also serves as a sealing agent when the structure is pressurized for habitation.

While the development of the first lunar base is still some years away, we have been working on some of the technologies that will be required to make the base self sufficient as well as allow it to contribute to the further exploration and settlement of the solar system through the resupply of propellants to spacecraft and the building of large space structures.