WSPC Demonstrates Feasibility of a Martian Jet Engine

Finding a Way to Directly Burn the Martian Carbon Dioxide Atmosphere

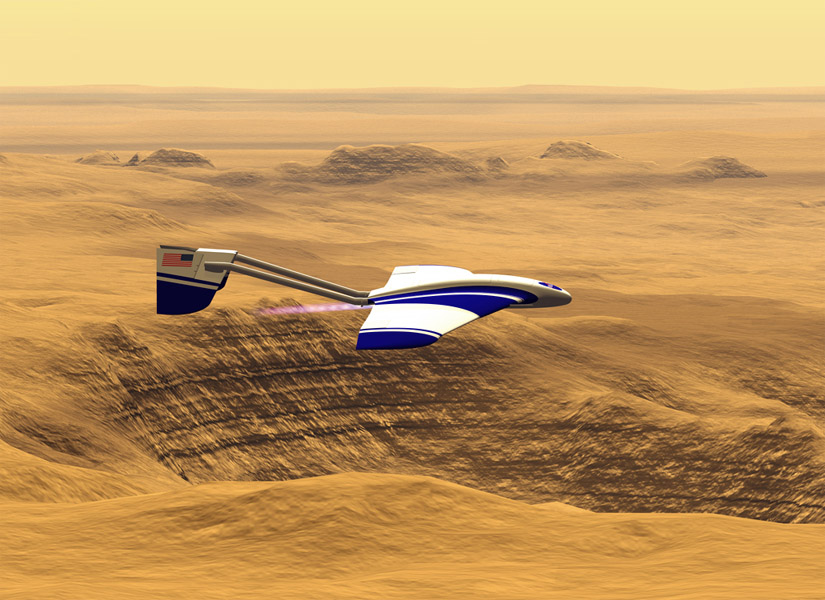

Wickman Spacecraft & Propulsion Company has successfully tested a jet engine that burns carbon dioxide. The jet engine would “breathe” and burn the Martian atmosphere as it flies along, just like airplane jet engines breathe the air on earth. What makes this Martian jet engine unique is that the Mars atmosphere is 95% carbon dioxide. Carbon dioxide is commonly used in fire extinguishers to put out fires on earth. Wickman engineers have developed a system where magnesium powder can be burned directly with carbon dioxide. Magnesium is believed to exist in the soil of Mars and is abundant on earth. This new jet engine would be ideally suited for the Mars Airplane.

The further exploration of Mars by robotic and manned missions will require a propellant taking advantage of what is available on Mars. Under NASA funding, Wickman Spacecraft & Propulsion Company (WSPC) started developing a new rocket engine and turbojet engine for use on Mars taking full advantage of the Martian atmosphere – carbon dioxide. WSPC looked at the possibility of burning the carbon dioxide directly. This would open up the possibility of Martian “air breathing” engines like jet engines.

While carbon dioxide is a common fire extinguishing agent, it burns very well with magnesium powder. While other investigators focused on single particle or very small quantities of magnesium combustion with carbon dioxide, Wickman plunged in with burning magnesium powder in large quantities in burners, rocket engines and jet engines. After testing many methods of burning magnesium with carbon dioxide, Wickman discovered a simple way of fluidizing the magnesium powder with kerosene and then burning it with carbon dioxide gas. The video above left shows the very first time this approach was successful. The coating of kerosene on the magnesium powder proved to be a problem in igniting the magnesium powder. Later research indicated that a better way to inject the magnesium powder into the combustion chamber was to use a inert carrier gas like nitrogen. The first open air test of a carbon dioxide and magnesium powder combustion chamber is shown at left.

Testing the Key Parts of a Martian Jet Engine

The development program was sponsored by the NASA Jet Propulsion Laboratory. During the program, a rocket engine, thruster and turbojet engine were built and tested by WSPC. The rocket engine had a thrust level of 40 lbs. The turbojet engine was designed to just overcome drag forces of a flying rover on Mars. The small jet engine was operated at less than a pound of thrust to compensate for these drag forces. It was operated for a few seconds at a time and then torn down and inspected by engineers. Low pressure combustion tests were also successfully done. These tests simulated the low pressure environment on Mars.

Shown at the right is a video of the jet engine burner can being tested in the open air. During the test, the flow of magnesium powder to the burner was changed to see how the burner responded and determine if the heat output from the burner could be controlled. A series of open air tests were done to make sure the stainless steel burner would survive before it was tested in the Mars jet engine.

A video of one of the final jet engine tests is shown at the left. You will hear the turbine being spun up. After the turbine reaches speed, the magnesium powder is slowly injected into the engine burner. You will see the smoke increase out the engine exhaust as the powder flow rate is increased. The engine then goes from start up to idle speed. This is noted by the change in pitch of the turbine as you can hear it go up to about 30,000 rpm. The engine was at idle for a few seconds before the turbine blades became clogged with carbon, shutting the engine down. The carbon clogging was due to stripping all of the oxygen off the carbon dioxide leaving only carbon behind. A redesign of the burner will fix this problem.

Click here for Russian translation by Clipart Magazine.