WSPC Developing Propulsion Concepts for a Mars Sample Return Mission

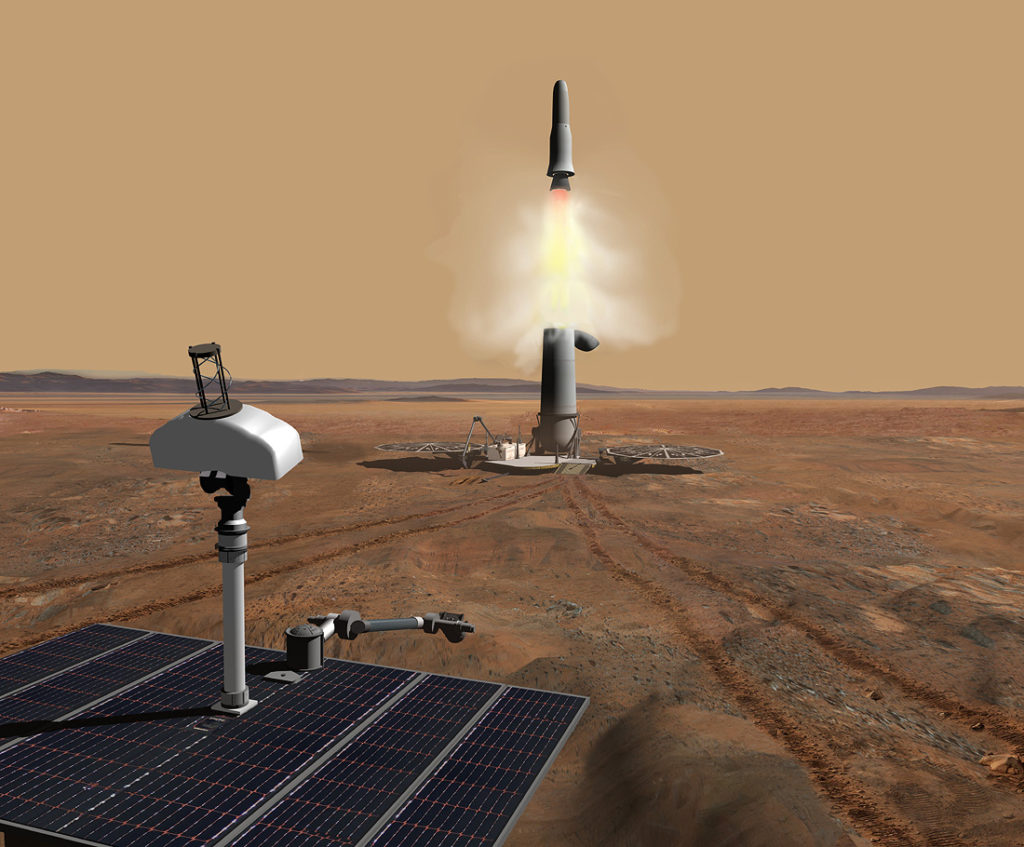

NASA is designing a Mars ascent vehicle (MAV) that will be launched from the surface of Mars to place a soil sample into a Mars orbit. One of the baseline designs uses two ATK Star solid rocket motors to propel the Mars sample into orbit. A major problem is that the solid rocket motors have no method of steering the vehicle since the nozzles are fixed. To overcome this problem, the baseline design uses cold gas thrusters for steering. For the final stage of flight, the vehicle is spun for stabilization.

There are two major problems with this solution. First, the cold gas system adds a lot of weight with a gas storage tank, pressure regulator and the weight of the gas. Second, spinning the vehicle means the sample container will be spinning when another orbiting vehicle tries to recover it and return to earth.

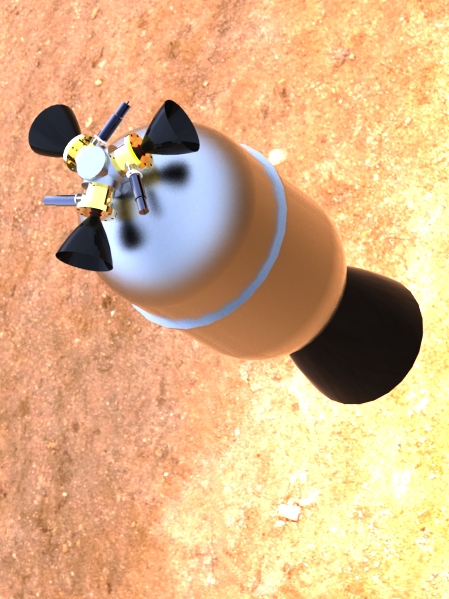

Wickman Spacecraft & Propulsion Company (WSPC) has developed an innovative solution that is reliable, lightweight and enhances the vehicle´s launch success probability, performance and potential for mission success. WSPC´s solution uses the hot gases from the combustion chamber and directs them through attitude control thrusters for steering (WSPC concept at right shows thrusters mounted on the forward end of STAR motor). Alternate designs locate the thrusters on the aft dome of the solid rocket motors.

A Major Technical Innovation

The major technical innovation is the ability to run gases with aluminum oxide particles at 5,600 F (3,093 C) through a control valve. The ability to the use the metallized, combustion gases for steering would eliminate the weight of a cold gas tank and regulators. It eliminates a spinning sample container in orbit and replaces it with a non-spinning orbiting container. This greatly simplifies the rendezvous and recovery of the Mars sample. The reduction in control components and lower weight would increase mission reliability and performance. The impact of this technology is to increase the chances of successfully returning a Mars sample to earth. This technology could also be used to bring back samples from other planets and moons.

Under a 2010 NASA contract, WSPC engineers created a layout of a MAV hot gas TVC system and tested key component materials with the MAV propellant. On July 26, 2010, WSPC successfully tested a heavyweight MAV hot gas control valve with the same propellant formulation as used in the baseline MAV first stage solid rocket motor. The propellant uses ammonium perchlorate as the oxidizer with 16% aluminum as the fuel plus the binder. All the parts survived without erosion despite the severe heat or heavy aluminum oxide content of the exhaust. During the test, the valve was throttled to a higher power setting about mid-way during firing. WSPC uses a unique, non-pintle design such that the valves readily lend themselves to large space booster applications unlike pintle nozzles, which are more practical for tactical missiles and small nozzles.