PSAN-I Phase Stabilized Ammonium Nitrate

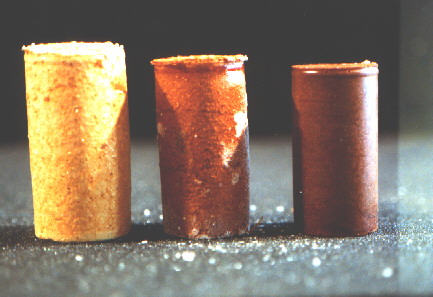

PSAN-I™ Ammonium Nitrate was developed by Dr. Adolf Oberth as a “clean burning” alternative to ammonium perchlorate oxidizers commonly used in solid propellant motors. The key was to develop an ammonium nitrate that was Phased Stabilized during temperature cycling. Unstabilized ammonium nitrate continues to grow bigger with each temperature cycle between room temperature and freezing and between room temperature and 120 degrees F. The middle cylinder in the picture to the left shows what happens to a composite propellant with unstabilized ammonium nitrate.. The cylinder on the right is phase stabilized with Dr. Oberth’s formula using 3% zinc oxide. It is its original size after a month of temperature cycling. The cylinder on the left was “stabilized” with Urea which obviously was less than successful.

A common misconception is that the zinc oxide is the actual stabilizing agent and all you do is mix zinc oxide powder with ammonium nitrate powder to get phase stabilized ammonium nitrate. Some have tried mixing zinc oxide with a solution of ammonium nitrate and water, dried it out, ground it up and thought they had a phase stabilized ammonium nitrate. Neither of these approaches will produce a phase stabilized ammonium nitrate because they do not form the necessary zinc diammine dinitrate complex which is the actual stabilizing agent.

In PSAN-I™, 3% zinc oxide is added to molten technical grade (99.9% pure) ammonium nitrate to produce a phase stabilized ammonium nitrate. But, it is not as simple as that. Water produce in the reaction must be purged from the melt before it is cooled to room temperature or phase stabilization is lost. There are other chemical parameters which also need to be adjusted in the production process or the phase stabilized ammonium nitrate will be even more hygroscopic than technical grade ammonium nitrate and produce accelerated cure of the propellant.

Wickman Spacecraft & Propulsion Company (WSPC) has continued with its research of phase stabilized ammonium nitrates based on our original patent. This has lead to the development of a Blend C ground PSAN and a Blend B atomized PSAN. Neither product is currently on the market, but are used instead in PSAN composite solid rocket propellant products sold by WSPC.

Ammonium Nitrate Composite Propellant

After discovering a low cost and non-toxic way of phase stabilizing ammonium nitrate, Dr. Oberth worked on improving the performance of ammonium nitrate propellants in the late 1980’s. Up until that time, AN propellants had a low specific impulse, were very hard to ignite and burned at a very slow rate.

After a great deal of experimentation, he found that using magnesium powder instead of aluminum powder produced an AN propellant that was easy to ignite, had a good specific impulse and burned at rates over twice that previously recorded with AN propellants.

Since his retirement in 1993 from Wickman Spacecraft & Propulsion Company, we have continued his pioneering work to produce ammonium nitrate propellants for use in small and large motors. Current research is focusing on obtaining faster burn rates and higher specific impulses.

This page has been translated into Russian (thanks to https://flyclipart.com/